Becoming an AI-powered manufacturer requires a step change and an innovation culture that gives employees permission to take risks and explore new ideas.

By Evan Ramzipoor, Workflow contributor

Last year, ServiceNow created the inaugural Enterprise AI Maturity Index to measure how AI is impacting organizations across industries worldwide. We found all sectors were grappling with low AI maturity levels. Manufacturing was no exception.

This year, we surveyed 4,473 global executives—including 1,428 automotive, consumer goods, and industrial manufacturers—to track how maturity levels have changed year on year. The results surprised us; maturity scores are lower now than in 2024. This year’s average maturity score for manufacturers declined by 10 points, on our 100-point AI maturity scale, from 45 to 35. In comparison, all respondents scored an average of nine points lower overall.

The reason? According to industry research created in collaboration with NVIDIA, AI is changing so quickly that manufacturing—like all other sectors—has struggled to adapt and integrate the technology.

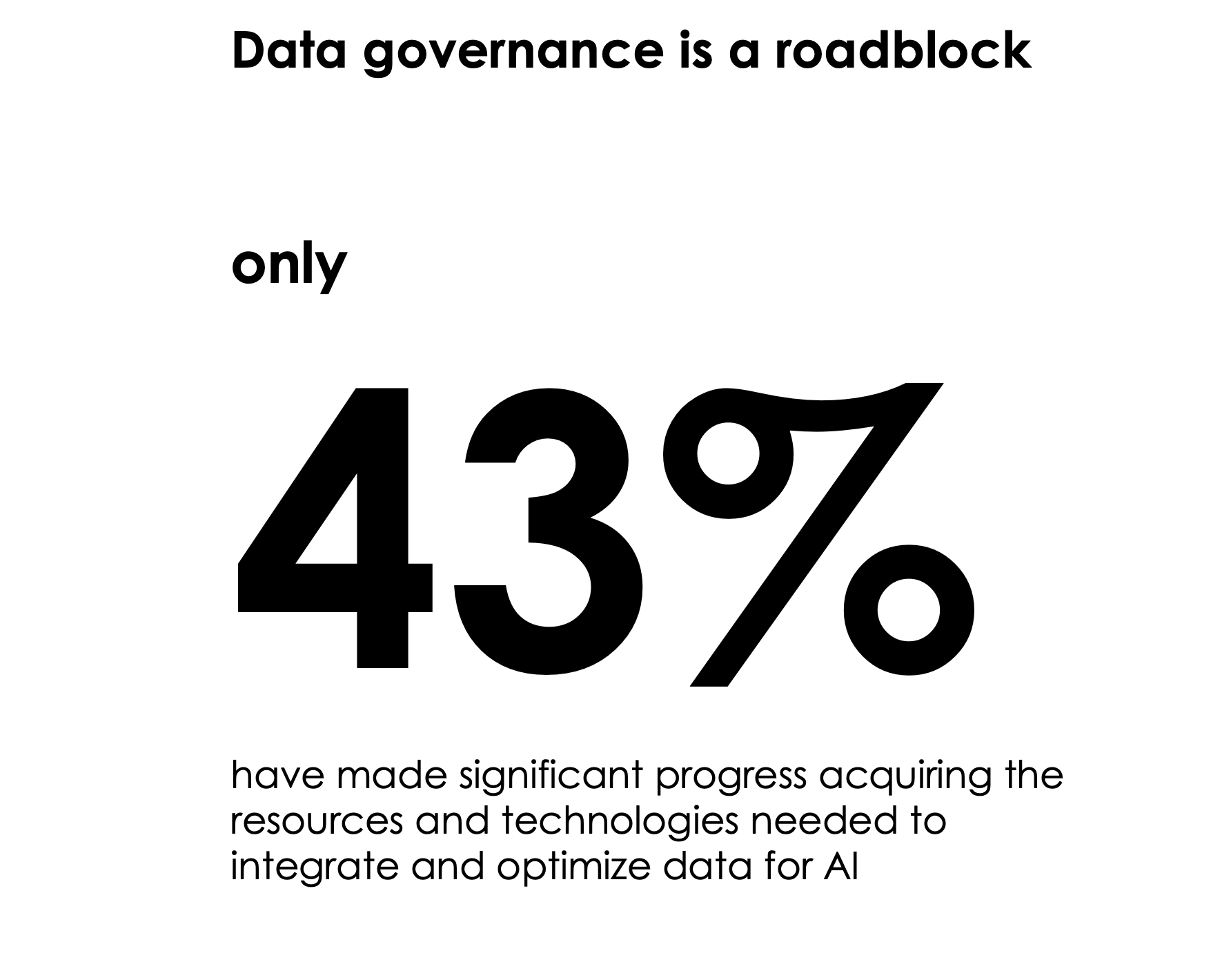

“Many manufacturers don’t have the data and IT foundation in place for AI,” explained Hartmut Mueller, chief transformation officer at ServiceNow. “They are not clear how to automate their value chain end to end in a customer-centric way.”

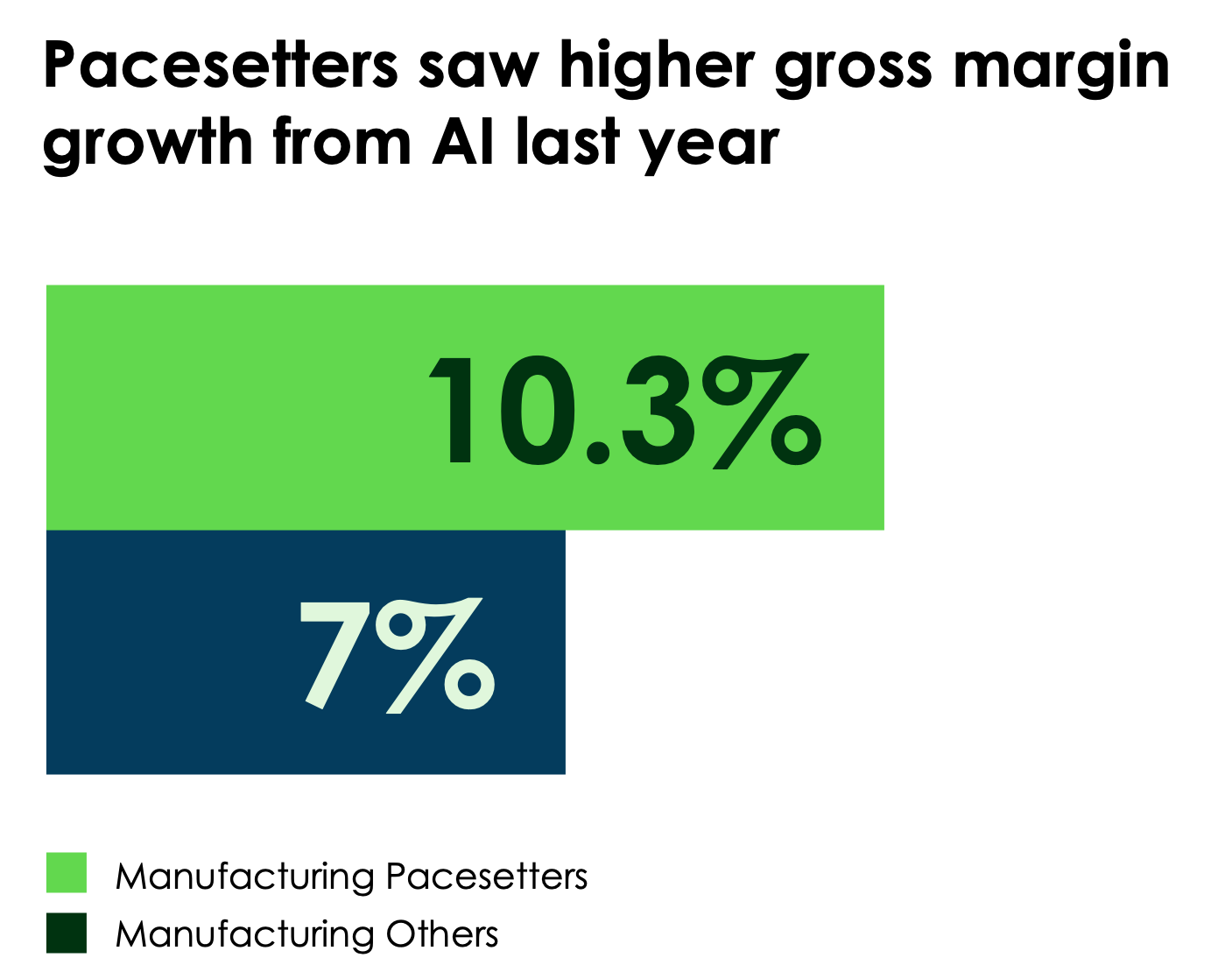

Yet there is reason for optimism. We found manufacturers are already seeing major dividends from their AI investments. A whopping 89% report higher productivity, and almost as many cite cost savings and revenue growth from their use of AI over the past year. Manufacturers also report an average 7.6% increase in gross margins from AI. As a result of these gains, 82% plan to increase their AI investments over the next year.

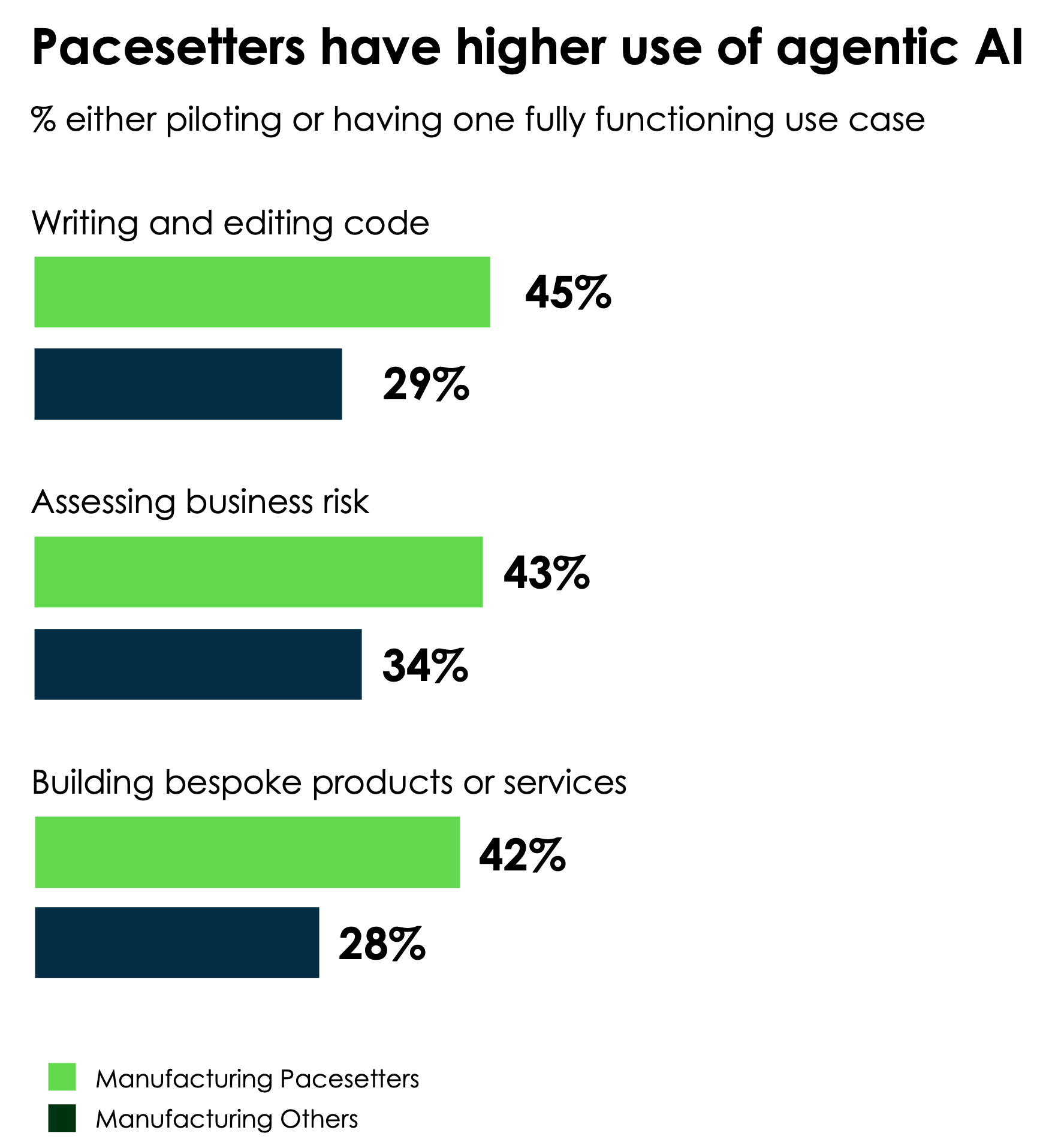

Our most mature cohort of manufacturers, which we call Pacesetters (18% of the total), are seeing even higher margin growth from AI than their non-Pacesetter competitors. This cohort leads the pack across all five pillars of AI maturity: AI strategy and leadership, workflow integration, talent and skills, data governance, and realizing value in AI investment.

As a result of their efforts, manufacturing Pacesetters saw greater improvements in productivity, profitability, stakeholder experiences, and speed of innovation than their sector peers.

Here are five best practices that set Pacesetter manufacturers apart from the rest:

SERVICENOW & NVIDIA PRESENT